Flexible

film turns heat to power

By

Chhavi Sachdev,

Technology Research NewsImagine a sensor in your car warning you that your tire needs to be replaced soon. Now, imagine that the power system for the sensor was made using something that resembles what you wrapped your leftovers in - metal foil.

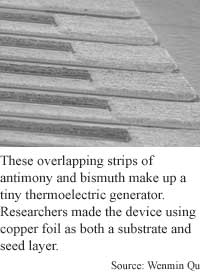

Researchers at the Dresden University of Technology in Germany have found a way to make tiny thermoelectric generators using copper foil as a template. The result is a cheap, flexible and recyclable generator that converts environmental heat into electricity.

The key to the process is using the copper foil template rather than silicon coated with a thin film of metal. The foil is cheaper, and using it as both the substrate - the base of any integrated circuit - and the seed layer - where the semiconductor crystals are grown - makes for a less complicated fabrication process.

Using copper foil precludes having a dedicated sacrificial layer that would have to be etched away, said researcher Wenmin Qu, a senior engineer for microsensors and microsystems at the Hydac Group in Germany.

The microsystem could use the heat produced in the axles of cars and trains by the motion of the wheels to detect damage inside the wheels or the axles, said Qu. “Ideal microsystems should be intelligent and self-powered,” he said.

Because the human body is a source of heat, someday, implanted medical microdevices could also be powered with a thermoelectric generator that operates on the body’s waste heat, said Qu.

“This generator could also be used in [the] reverse direction…as a cooling element,” for computer chips and other electrical devices, he said. Applying electrical power to the generator cools it, he explained.

The generator, which is as flexible as copper wire, comprises 100 pairs of antimony-bismuth strips connected thermally and electrically. The entire module measures 16 by 20 millimeters square, or about the size of a thumbtack. Each strip in the module is about 10 microns high, 40 microns wide and 20 mm long.

The researchers made the generator by patterning the copper foil using photolithography, then electrodpositing antimony and bismuth on the pattern. They then added an epoxy film to the antimony-bismuth strips and hardened it using ultraviolet light. “In the last step, the initial copper sheet is entirely etched away, resulting in the antimony-bismuth strips being embedded in the epoxy film,” said Qu.

The next step for Qu and his colleagues is designing a more efficient thermoelectric generator based on bismuth telluride, he said.

The antimony-bismuth module can generate 250 millivolts, or a quarter of a volt when the temperature difference between the ends is 30 degrees celsius, said Qu. The bismuth telluride version could provide five times the power of the antimony bismuth model, he said.

“Theoretically, the module with bismuth telluride will provide a voltage of about 1.6 volts at a temperature difference of 30 degrees [celsius]. The real value could be a little lower than [1.6 volts]. However, we believe it would not be lower than 1.2 volts,” said Qu.

The researchers are also looking into using titanium as a substrate instead of copper foil, even though it is more expensive; in experiments, titanium did not contaminate either antimony or bismuth layers, while the researchers found small traces of copper contaminating the electrodeposited antimony layer.

They hope to have a functional, equally flexible bismuth telluride module within 2 to 3 years, according to Qu.

“There are a host of possible applications in microsystems of autonomous electrical power sources that can run on low-temperature waste heat,” said Yogendra Joshi, a professor of mechanical engineering at the University of Maryland. “The key challenge is the ability to generate decent amounts of power and the ability to integrate the device with the rest of the microsystem,” he said.

“The authors have shown success in doing this with [antimony-bismuth] micro thermocouples, with modest electrical power generation,” said Joshi.

Qu's research colleagues were Matthias Plötner and Wolf-Joachim Fischer of the Dresden University of Technology. They published the research in the Journal of Micromechanics and Microengineering, March 2001. The research was funded by the Association of Industrial Research Organisations (AiF) in Germany.

Timeline: 2 - 3 years

Funding: Institute

TRN Categories: Microelectromechanical Systems (MEMS)

Story Type: News

Related Elements: Technical paper, "Microfabrication of thermoelectric generators on flexible foil substrates as a power source for autonomous microsystems" in the Journal of Micromechanics and Microengineering, March 2001, 146-152

Advertisements:

May 16, 2001

Page One

Rough tools smooth design

Tightening photonic bonds strengthens security

Tunable superconductor makes better circuits

Flexible film turns heat to power

Natural force drives molecular ratchet

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.