Nanotube fabric looms large

By Eric Smalley, Technology Research NewsElectricity-generating flags, bulletproof vests, super batteries, microscopic machines and chemical sensors could all one day be made from the same material: fabric woven from fibers that contain carbon nanotubes.

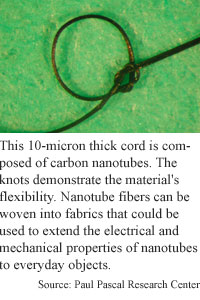

Researchers at the Paul Pascal Research Center, a national laboratory in France, have developed a process for spinning carbon nanotubes into fibers. Nanotubes are sheets of carbon atoms rolled up into tubes about a nanometer in diameter. A nanometer is one millionth of a millimeter.

The process preserves the electrical and mechanical properties of the nanotubes. Nanotubes are the strongest known objects. They are good at conducting and holding electrical charges, and bind well to oxygen and hydrogen molecules. When they bend, their electrical resistance changes, making it possible to convert mechanical energy to electricity. The fibers provide a means of weaving these traits into everyday objects.

"These [fibers] could be useful to make bulletproof vests or to make fabrics that in the wind can move and produce electrical energy," said Philippe Poulin, a materials scientist at Paul Pascal Research Center.

Producing microscopic fibers could also be a good way of harnessing nanotubes for nanotechnology, said Poulin. "Small devices like sensors or actuators that can be used in the body... people are dreaming about things like that, and carbon nanotube fibers could be used for such applications," he said.

Potential applications include electromechanical actuators, supercapacitors, distributed sensors, hydrogen storage media, materials for harvesting electrical energy and high strength composite materials, said Ray H. Baughman, a materials scientist at Honeywell who is refining and exploring applications for the nanotube fiber process.

The process involves suspending nanotubes in a surfactant solution, which is essentially liquid soap that keeps the nanotubes from clumping together. The suspended nanotubes are then injected into a flowing solution that contains polyvinylalcohol. The flow aligns the nanotubes in one direction and the polyvinylalcohol replaces some of the surfactant molecules, allowing the nanotubes to clump together. The flow also allows the researchers to produce strands of fiber as long as one meter.

"You want to take advantage of [the] mechanical and electronic properties of nanotubes. So that means when you make fiber and ribbons you have to align the nanotubes along the ribbon or fiber direction," said Jie Han, a research scientist at the NASA Ames Research Center. "This process can deal with this alignment pretty well compared to other technologies."

An important benefit of the process is that it can be easily scaled up for large scale production, said Han. It is also compatible with commercial processes for producing synthetic fibers.

"Now, I think it's critical to improve the physical properties of the fibers, their conductivity, their mechanical strength," said Poulin. In particular, the fibers did not exhibit the phenomenal strength of the nanotubes themselves. " It [is] still far from the potential we can expect," he said.

One problem is that the process used carbon soot that is about 50 percent carbon nanotubes, said Baughman. The process did not work with pure carbon nanotubes created with the standard techniques. However, it did work with pure nanotubes produced using a high-pressure technique developed at Rice University, he said. "[They] spin exceptionally well to produce fibers that largely comprise single-wall carbon nanotubes," Baughman said.

The fibers are twice as strong using the Rice nanotubes as fibers made with the nanotube-soot mixture, though still much weaker than their potential, he said

Baughman also found that the fibers were weakened in water, but annealing them solves that problem, he said. Annealing is the process of hardening materials by heating them.

Researchers should be able to produce large quantities of useful fibers containing carbon nanotubes in three to five years, said Poulin. The process must be made faster and the nanotubes more precisely oriented before the process can be scaled up, said Baughman.

Poulin's colleagues were Brigitte Vigolo, Alain Penicaud, Claude Coulon, Cedric Sauder, Rene Pailler, Catherine Journet and Patrick Bernier. They published their work in the November 17, 2000 issue of Science. The research was funded by the Centre Nationale de la Recherche Scientifique. Baughman's research was funded by DARPA.

Timeline: 3-5 years

Funding: Government

TRN Categories: Semiconductors and Materials

Story Type: News

Related Elements: Image, Technical paper "Macroscopic Fibers and Ribbons of Oriented Carbon Nanotubes," Science, November 17, 2000

Advertisements:

December 13, 2000

Page One

Nanotube fabric looms large

Silicon nanocrystals glow

Exploratory robot hops and rolls

Lasers flex gel muscles

Atomic scale wire speeds electrons

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.