Biochips

get pumped

By

Kimberly Patch,

Technology Research NewsAn important aspect of making microscopic machines is producing minuscule versions of basic mechanical parts like pumps that can shunt around tiny amounts of matter.

Scientists from the Colorado School of Mines have constructed two types of valves and two types of pumps that are not much bigger than a red blood cell. "We have the ability to locally control minute volumes of fluid as well as individual particles or cells in microsystems," said John Oakey, a Colorado School of Mines researcher.

The devices, which are an order of magnitude smaller than existing micro pumps, are a step toward making microscopic biological and chemical labs-on-a-chip, including sensors or drug delivery vehicles that could be implanted within human bodies.

The pumps are twice the size of red blood cells and push forward one millionth of a liter, or about one 20th of the volume of a drop of water, per hour.

The key to the microscopic mechanics is positioning groups of spherical particles within tiny channels and using them to coax liquid to flow in a particular direction, said Oakey. The insight that led to the devices was realizing that colloidal spheres could be used as the active parts, he said.

A colloid is a liquid mixture that contains particles finer than those generally suspended in a solution.

These colloidal building blocks measure three microns across, and the mechanical devices just under 10 microns, or one hundredth of a millimeter. A red blood cell is about five microns in diameter.

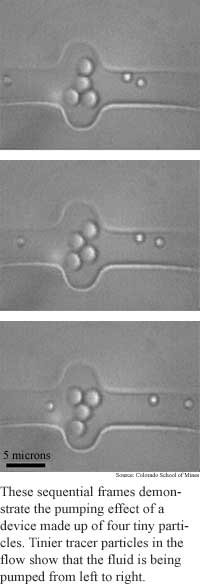

To make the parts, the researchers corralled the colloids they needed from the solution and positioned them using laser tweezers. Laser tweezers are computer-controlled laser beams that bombard the minute particles with photons in order to manipulate them in a way similar to the way a strong wind can move solid objects. The pumps "operate by controlling the motion of a few individual colloidal particles that comprise the pieces of the pump," said Oakey.

To make a valve the researchers used laser tweezers to line up a group of colloids as they floated within the tiny channel, then polymerized, or cemented the particles together to form the flap of the valve. "In a focused laser beam, multiple particles will align... with the beam," said Oakey. "The interaction of the trapped particles and the surrounding hydrogel [solution] results in the polymerization," he said.

The researchers two pump designs -- gear and sine-wave -- operate on the same principles as their macroscopic cousins, said Oakey.

Gear pumps are generally made of a pair of gears that trap fluid against the walls of a chamber. The trapped fluid causes a drop in pressure across the gears and the meshing of the gears in the center prevents fluid from falling back through the gears.

Although the round particles and straight-walled channels don't fit as precisely as precision-machined gears, the basic effect is the same, said Oakey. "The particles in our pump are always in contact in the center... like meshing gears, [and] around the outer perimeter the particles are almost contacting the walls. These gaps around the perimeter trap fluid and [push] it forward incrementally."

A screw, or sine-wave pump works in a similar way. As the screw mechanism turms, a plug of fluid is trapped, propelled along with the threads, and spit out the other side. The sine-wave version works the same way, "except in two dimensions and with much smaller plugs of fluid," said Oakey.

The researchers have also constructed two types of valves: a passive check valve, which allows fluid to flow in only one direction, and a similar valve that is moved around and opened and closed using laser tweezers. "These valves... are simply a string of particles polymerized together in situ, connected to a larger particle which serves as a tether," said Oakey. The tether particle can either be attached to the wall of a channel or held in place using laser tweezers.

The researchers thought of using colloidal particles to construct tiny mechanical parts while using a particular set of laser tweezers they had constructed as a tool to study the behavior of individual colloidal particles. "We constructed an optical trap capable of rapidly manipulating individual particles," Oakey said. Doing so "led us to recognize the potential utility of incorporating individual colloidal particles within microchannels," he said.

The researchers' prototype pumps are already about an order of magnitude smaller than existing devices, said Oakey. And in theory, colloidal pumps could be made considerably smaller, said Oakey. "They could potentially be scaled down by at least an order of magnitude," he said.

Aside from the colloidal pumps, "the smallest pumps I know of [move an elastic] membrane using pneumatic actuation," said Oakey. These have reached a size limit due to the dimensions of the membrane, he said. At a certain point the membrane itself "prevents deflection into channels which are too narrow -- the aspect ratios just get prohibitive."

What may eventually prove a size limitation for colloidal pumps is the wavelength of light used by the optical tweezers, said Oakey. The colloidal pumps "can theoretically be made... down to the diffraction limit of the optical trap, and perhaps smaller," he said.

The researchers intend next to combine several of their microscopic devices into a working array, said Oakey. Operating many pumps in parallel would increase the amount of liquid the device could pump per hour, said Oakey. The main goal of making a very small pump, however, is to accurately control a very small amount of liquid, he said.

Many tiny pumps could eventually be included in more complicated systems like quickly-acting biological assays or chemical sensors that could be used within living bodies, said Oakey. "We are interested in [combining] device arrays with sensing and feedback operations," he said. "Colloid-based pumps and valves... could be incorporated within implantable devices in vivo and used as monitoring or targeted drug delivery vehicles," he said.

Oakey's research colleagues were Alex Terray and David W. M. Marr. They published the research in the June 7, 2002 issue of the journal Science. The research was funded by the National Science Foundation (NSF) and the National Aeronautics and Space Administration (NASA).

Timeline: 2-5 years

Funding: Government

TRN Categories: Microfluidics and BioMEMS

Story Type: News

Related Elements: Technical paper, "Microfluidic Control Using Colloidal Devices," Science, June 7, 2002.

Advertisements:

August 21/28, 2002

Page One

Biochips get pumped

Chip design aims for quantum leap

Net traffic mimics earthquakes

Stamps and glue make circuits

Shortcuts lighten wireless load

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.