Piezoelectric sliver forms sensor

By Kimberly Patch, Technology Research NewsTwo things make it difficult to measure very tiny things: finding instruments that can sense changes on a microscopic scale, and finding a way to convey these measurements to the macro world.

A group of Princeton University researchers is putting together arrays of microcantilevers that may eventually be capable of measuring very small concentrations of molecules in environments like blood vessels.

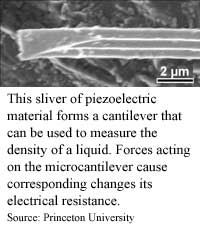

One key to the work is that the microcantilevers, diving-board-like instruments that measure 10 microns wide and 100 to 1,000 microns long, are made of piezoelectric ceramic. This material gives off current when it vibrates.

The amount of current is easy to measure from the macro world, and the current correlates with the rate of vibration. "The idea is when they oscillate up and down they introduce charges on their surface which can be detected directly using electronics," said Jeffrey Carbeck, assistant professor of chemical engineering at Princeton.

The researchers have shown that the microcantilevers can measure liquid viscosity and density. "As the fluid [moves] faster there's going to be greater resistance for the cantilever to bounce up and down, just like as you're driving down the road the faster you go the more force there is on your hand [from the airstream] as you tip it away from horizontal," said Carbeck.

The researchers next step is using the cantilevers to sense whether specific molecules are present in a liquid. They're working on applying a nanopore coating that will increase the microcantilever surface area by 100 times. The coating is a sort of 3-D honeycomb structure that has horizontal passages among vertical honeycomb channels.

Molecules that bind specifically to molecules of a substance to be measured can be embedded in these channels. "It could be a DNA molecule that binds to another DNA molecule [or] it could be a protein that recognizes some molecular signal of disease," said Carbeck. As the embedded molecules pick up molecules of the substance, the cantilever becomes heavier, which changes its rate of vibration.

There are two phases to the project, said Carbeck. "The first phase, which I would qualify as the next three to five years, is making these sensors fully functional, integrating the coating, integrating receptors and actually allowing them to sense in a laboratory environment."

As part of this, the researchers will also zero in on the optimum size for the microcantilevers, which is somewhere between one and 10 microns wide, said Carbeck. "One way to make it more and more sensitive is to make it smaller," he said. This is because the heavier the molecules are in relation to the microcantilever, the easier it is to sense them, just as a diving board will oscillate more after a heavier diver has jumped off.

But the cantilevers don't work if they're too small. "As you start to make things very small... they start to lose energy to the environment," said Carbeck. When this happens, "rather than vibrating up and down at a well-defined frequency [it] becomes a range of frequencies," he said. This means you can no longer correlate the motion of the cantilever with the number of molecules captured on its surface, he said.

Another technical challenge is depositing the coating. "We're developing technologies for making very thin films out of this high surface area coating. You have to get the coating less than one micron thick... to be compatible with the one micron cantilever [and] also so it does not crack when it dries," he said.

The researchers are drawing together several existing technologies in new ways in order to to form the sensors, said said Arun Majumdar, a mechanical engineering professor at the University of California at Berkeley. "I think the idea is good. The principal of using cantilevers is not new. Using piezoelectric cantilevers to actuate is not new. But using piezoelectric cantilevers to measure viscosity may be new [as well as] using piezoelectric [cantilevers] with a honeycomb structure," said Majumdar.

Once the researchers put the pieces together, the microcantilevers could be used to measure concentrations of molecules in laboratory settings. They could also be used as an alternative to the cantilevers used in atomic force microscopes, which are measured using laser beams, said Carbeck. "You could... instead create surface force microscopy cantilevers out of this material and detect the deflection electronically. Also, [by] fabricating [cantilevers] into arrays you can sense a larger area," he said.

The second phase is making these sensors biocompatible, said Carbeck. "You want to figure out how to protect them from things like the immune response of the body, which is to deposit proteins and cells that form scar tissue on these materials. That's a separate line of research... so you're talking about 10 years out before you have a functional sensor that's also biocompatible," he said.

Ultimately, the project is aimed at developing arrays of microcantilevers that can reside in the human body and measure several different molecules or physical properties at once, said Carbeck. "You would like to have sensors that can detect molecular signals of disease that can be implanted in non-invasive way [in] say, the bronchiole of the lungs or in microcapillaries or arteries,” he said.

The project was initially funded by the National Science Foundation. The continuing work to refine the microcantilevers and add the coating is funded by NASA. Carbeck's colleagues in this work are Ilhan Aksay, Shilpa Bhansali, and Jessica Jarvis.

A technical paper on the cantilevers' ability to measure liquid viscosity and density has been accepted by the Journal of Applied Physics. The researchers who worked on this paper were Wan Y. Shih, of Drexel University and Princeton, Xiaoping Li, Huiming Gu and Wei-Heng Shih of Drexel, and Aksay, who joined a second set of researchers to publish a paper on the nanopore coating in the January 25, 2000 issue of Langmuir. That group also included K. M. McGrath of the University of Otago, D. M. Dabbs and N. Yao of Princeton, and K. J. Edler and S. M. Gruner of Cornell University.

Timeline: 3-5 years, 10 years

Funding: Government

TRN Categories: Applied Computing; MicroElectroMechanical Systems (MEMS)

Story Type: News

Related Elements: Photo 1, Photo 2, Technical paper, "Simultaneous Liquid Viscosity and Density Determination with Piezoelectric Unimorph Cantilevers," accepted for publication, Journal of Applied Physics; Technical paper, "Silica Gels with Tunable Nanopores through Templating of the L3 Phase," Langmuir, January 25, 2000.

Advertisements:

November 22, 2000

Page One

Holey chips channel light

Piezoelectric sliver forms sensor

Self-tuning software speeds networks

Software cross-sorts gene data

Electron beams turnout tinier tubes

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.