Frosted nanotubes make metal wires

By Eric Smalley, Technology Research NewsLike freezing rain coating tree branches with a layer of ice, vaporized metal in a Stanford University laboratory coats carbon nanotubes in a process that yields metal wires as thin as five nanometers in diameter.

A nanometer is one millionth of a millimeter. Metal wires of that scale are beyond the abilities of the lithographic techniques used to make integrated circuits. Experimental lithographic techniques can produce wires as small as 25 nanometers in diameter, and commercial photolithographic techniques can produce wires as small as 125 nanometers in diameter.

The nanowire-on-nanotube process could give electronics manufacturers a new fabrication technique to cope with the relentless drive to make smaller circuits. Metal nanowires could have other uses as well because they are expected to have different properties than larger metal wires, including superconductivity.

Other researchers have produced smaller metal wires, including some as small as one nanometer in diameter. The advantages of the Stanford technique are its relative simplicity and the broad range of metals it works with.

"With this approach you can make a variety of metal nanowires. It doesn't matter what metal... you can just put them on to the tube and make them into metal nanowires," said Hongjie Dai, an assistant professor of chemistry at Stanford.

The first step in the process is producing single-walled carbon nanotubes, which are typically a little over one nanometer in diameter. The nanotubes are created on tiny grids so that only the ends are supported, leaving the bulk of the nanotubes suspended in air. The next step, applying a buffer layer of titanium to the nanotubes, is the key to the process.

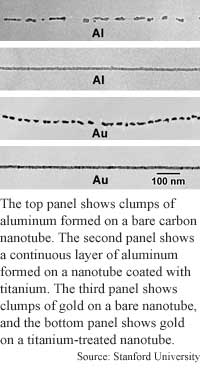

Because most metals don't bind well to carbon nanotubes, vaporized metals usually form discrete particles along nanotubes rather than continuous wires. Titanium, however, does bind well to carbon nanotubes, and other metals bind well to titanium.

The researchers have produced gold, palladium, iron, aluminum and lead nanowires between five and 10 nanometers in diameter and as long as 100 microns. Each wire is a composite with a carbon nanotube at the center, a layer of titanium in the middle and a layer of metal on the outside.

The process should be able to scale up to support manufacturing, said Dai. "You can imagine having a wafer full of those suspended nanowires," he said. "Nanowires in general could have some potential commercial application in about five years."

The next step of the project is studying the mechanical, electromechanical, electrical and magnetic properties of the metal nanowires. The researchers also plan to test niobium, vanadium, scandium and tantalum as alternative buffer materials to determine if they produce nanowires with different properties.

Dai's colleague was Yuegang Zhang. They published their work in the November 6, 2000 issue of the journal Applied Physics Letters. The research was funded by the National Science Foundation and ABB Ltd. of Switzerland.

Timeline: <5 years

Funding: Government, Corporate

TRN Categories: Semiconductors and Materials; Nanotechnology

Story Type: News

Related Elements: Image 1, Image 2, Image 3, Image 4; Technical paper, "Formation of metal nanowires on suspended single-walled carbon nanotubes," Applied Physics Letters, November 6, 2000

Advertisements:

December 6, 2000

Page One

Biomotor powers propeller

Safe havens offer practical quantum processing

Mechanical data storage goes massively parallel

Frosted nanotubes make metal wires

Interference delivers atomic details

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.