Disks

set to go ballistic

By

Eric Smalley,

Technology Research NewsOne of the challenges to cramming more information onto computer hard drives is making a sensor sensitive enough to measure the presence or absence of a magnetic field in a microscopic bit of material.

Reading a bit means sensing if its magnetic field affects the flow of electrons through an electric circuit. If the magnetic field is strong enough to change a sensor's electron flow, the bit represents a 1, if not, it is a 0. The smaller the bit, the smaller its magnetic field, and the harder it is to sense the difference between a 1 and a 0.

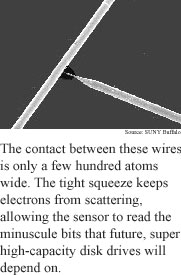

Researchers from the State University of New York at Buffalo have used an effect dubbed ballistic magnetoresistance to make a tiny prototype sensor that is 15 times as sensitive as the giant magnetoresistance sensors used in today's disk drives. The T-shaped sensor consists of a pair of wires connected by only a few hundred atoms.

Because the sensor is very small as well as sensitive, it could be used to read tiny, closely packed bits. "Due to the nanoscale of the sensor, bit size can be reduced to... terabit-per-square-inch densities," said Harsh Deep Chopra, an associate professor of materials science and engineering at SUNY Buffalo. A terabit is 125 gigabytes, and a DVD holds 4 gigabytes. A CD-sized magnetic disk with such small bits could hold 1,800 gigabytes, or about 450 DVDs worth of information.

The key to making sensors that can read smaller bits is increasing the magnetoresistance of the sensor, or read head, used to distinguish the magnetic states of the bits. The higher a material's magnetoresistance, the greater the difference in the number of electrons flowing through it when it is surrounded by a magnetic field versus when it is not. If the difference is significant, it can be used to distinguish weak magnetic fields like those of very small bits that represent 1's from bits that have no magnetic field and represent 0's.

Ballistic magnetoresistance produces a greater difference between 1 and 0 signals and other types of magnetoresistance, but the challenges to using it in disk drives is that it works best with either very strong magnetic fields or extremely low temperatures. Strong magnetic fields can't be used with small bits, and a low-temperature requirement makes for impractical devices.

The Buffalo researchers got around these potential restrictions when they discovered that the right size and shape of the contact point in the tiny wires of a sensor increases the ballistic magnetoresistance effect to the point where it can be used with weak magnetic fields at room temperature.

The researchers' ballistic sensor consists of two nickel wires 125 microns in diameter connected to form a T. A micron is a thousandth of a millimeter, and a human hair is about 75 microns thick. The researchers sharpened the end of one wire at the T junction to a 40-nanometer point to make an extremely small contact between the two wires. A nanometer is one thousandth of a micron, or about the length of 10 hydrogen atoms in a row.

When the sensor is in a magnetic field, the magnetic orientations of its electrodes align, making current flow more easily.

In addition, electrons flow even more easily through the sensor because of its small size. As electrons flow through materials like metal, they ordinarily scatter, bouncing in different directions. An electrical current arises when the average of all the movement is a flow in one direction. In wires only a few nanometers wide, however, the scattering stops and electrons flow straight through, or ballistically. The sensor allows electrons to flow this way because the contact surface at the T junction between the electrodes is only a few hundred atoms

In the absence of a magnetic field, the magnetic orientations of the electrodes in the researchers' sensor are opposite, which increases the device's resistance to electrical currents.

The sensor's small size also gives it an an advantage where resistance is concerned. Electrons have spin, which is similar to a magnet's North and South poles. If an electron's spin is aligned with the magnetic orientation of an electrode, it can pass through. If not, it is blocked. If the contact between the sensor's electrodes were larger, a few electrons would reorient their spins and pass through, reducing the resistance. But because the contact is so small, the electrons don't have time to reorient, which gives the device a higher resistance.

The combination of ballistic electron flow in the presence of a magnetic field and greater resistance in the absence of a magnetic field means a greater difference in electron flow than is possible with today's giant magnetoresistance devices. This makes for a more sensitive sensor.

In low magnetic fields at room temperature, the electrical resistance of the researchers' sensor is 33 times greater than when no magnetic field is present, allowing the sensor to read bits so small that one trillion of them could fit in a square inch, according to Chopra. Previous ballistic magnetoresistance experiments have yielded increases in resistance of as much as seven times. The giant magnetoresistance used in today's disk drives doubles electrical resistance.

Making practical storage devices that use ballistic magnetoresistance should be fairly straightforward because it is similar to giant magnetoresistance, said Chopra. Giant magnetoresistance devices use two thin layers of magnetic material separated by an even thinner non-magnetic layer. Because the magnetic layers have opposite magnetic orientations, passing a current of electrons through both layers is difficult: one layer blocks electrons that have one spin orientation while the other layer blocks electrons of the other orientation. Adding a magnetic field causes the magnetic orientations of the two layers to align and so block electrons of only one spin orientation.

"The good news is that the effect is like giant magnetoresistance except it is... huge and it comes packed in a sensor size that is atomic scale," said Chopra. More work needs to be done to closely control the stronger ballistic effect and assess its long-term stability, he added.

The device's strong effect at room temperature and in small magnetic fields makes it "potentially very interesting" for data storage technology, said Caroline Ross, a professor of materials science and engineering at the Massachusetts Institute of Technology. "We still need to understand exactly the mechanism for the effect," she said.

The tiny contact point between the wires forces the boundary of the magnetic field to be very narrow, effectively blocking electrons, said Ross. "Hence this phenomenon is a direct result of the small size of the contact," she said.

The ballistic magnetoresistance the researchers produced could be used in practical applications in 4 to 6 years, said Chopra.

Chopra's research colleague was Susan Hua. They published the research in the July 1, 2002 issue of the journal Physical Review B. The research was funded by the National Science Foundation (NSF) and the Department of Energy (DOE).

Timeline: 4-6 years

Funding: Government

TRN Categories: Data Storage Technology; Materials Science and Engineering; Physics

Story Type: News

Related Elements: Technical paper, "Ballistic magnetoresistance over 3000% in Ni nanocontacts at room temperature," Physical Review B, July 1, 2002

Advertisements:

July 24/31, 2002

Page One

Disks set to go ballistic

Two-step queries bridge search and speech

Implant links nerve cells to electronics

Silicon chips set to go atomic

Light switch promises powerful computers

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.