Bulk

nanotubes make clean crystals

By

Chhavi Sachdev,

Technology Research NewsCarbon nanotubes have often been compared to cooked spaghetti; the tiny tubes, whether self-assembled or manufactured chemically, tend to be tangled messes with variable properties. Separating the two basic types of nanotubes - semiconductors and metals - is usually an arduous task.

Researchers at IBM have come up with an efficient method to make uniform metallic nanotubes. Instead of a congealing imbroglio of pasta pieces, the resulting array lines up like ten thousand neatly stacked, matching strands of dry spaghetti arranged in a hexagonal bundle.

Each nanotube is the same size as its neighbors and also shares the same electronic and chemical properties. Since the tubes are perfectly crystalline, they are also stronger, smoother, lighter and more flexible than regular carbon nanotubes, said James Gimzewski, who was on the IBM research team and is currently a chemistry professor at the University of California at Los Angeles.

Nanotubes have a wide range of potential applications from environmental sensors to components of nanoelectronic circuits. Uniform properties will make it easier for researchers to apply nanotubes practically. Nanotubes could eventually be used as hydrogen energy storage devices, gas detectors, biochemical markers, nanoscale tweezers, or as a building material for car and plane bodies, according to the researchers.

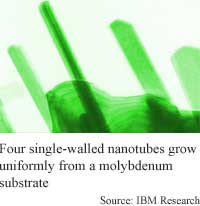

To make the uniform nanotubes, the researchers evaporated alternate layers of buckyballs and molecules of a nickel catalyst through a shadow mask, or screen, containing holes 300 nanometers in diameter. The catalyst causes the buckyballs, soccer-ball shaped molecules made of 60 carbon atoms, to unzip and form nanotubes. The researchers used heat and magnetic force to control the process, making the nanotubes uniformly aligned and structurally identical. Other chemical vapor deposition processes produce larger, discrete nanotubes.

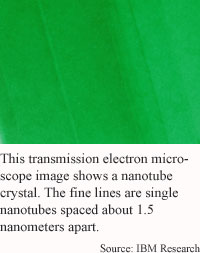

Each tube in the array is about 1 nanometer wide, which is about 75,000 times narrower than a human hair. Each hexagonal crystal-like array contains about 10,000 nanotubes spaced about 1.5 nanometers apart. “The crystals can be up to 2 microns wide at the moment,” said Gimzewski. A micron is one thousandth of a millimeter, or roughly one seventy-fifth the width of a human hair.

The entire process takes about “twenty five minutes with a coffee break in between,” said Gimzewski. In that time, the researchers produced 30,000 bundles of 10,000 nanotubes, or a million billion nanotubes. The area these tubes occupy is about half an inch square.

The tubes produced are about a hundred times stronger and ten times lighter than steel, and are defect-free, according to Gimzewski. They are also incredibly flexible. When you bend a plastic pipe, for example, and then unbend it, a kink always remains. These tubes, when they unbend, “just go back to being perfect again,” Gimzewski said.

Another property of the tubes is that they conduct heat along their lengths but not across their widths. This could allow them to efficiently dissipate heat in a computer chip.

“The results are impressive,” said Phillipe Poulin of the National Center for Scientific Research, (CNRS) at the University of Bordeaux, in France. “For the first time, single wall carbon nanotubes are produced as a perfect bulk material,” he said. Although the method might be difficult to scale up for large production, “it definitely opens new and very promising routes to the use of carbon nanotubes in electronics,” he said.

“I think that this work will motivate extensive research in different laboratories to try to improve the yield and to explore the commercial interest of the obtained materials,” Poulin said.

“If this synthetic method can produce [a] large yield of nanotube single crystals…these nanotube single crystals will have tremendous potential for fundamental research,” said Peidong Yang, assistant professor of chemistry at the University of California at Berkeley. “Immediate things to do would be…intercalation” of chemicals such as potassium or sodium into the spaces between the nanotubes, in order to induce superconductivity in the crystals, Yang said.

“The challenge is how long could you make them?” said Gimzewski. His ultimate goal is to be able to spin the tubes “like a nanospider,” he said. The nanotube thread would be so fine, that it would be invisible. This might be “a bit sci fi, however I am pretty sure that a filament would have applications as a cutting tool superior to lasers in medicine,” he said. “We have the evidence that you can make such things.”

The researchers are aiming to increase the scale of nanotube manufacturing and make the process less expensive. One possibility is to use a less expensive carbon source than buckyballs, said Gimzewski.

Single-walled carbon nanotube crystal-like arrays could be in practical use within the next 10 years, Gimzewski said.

Gimzewski’s colleagues were R. R. Schlitter and J. W. Seo at IBM’s Zurich Research Laboratory, C. Durkan, Maria S. M. Saifullah, and Mark Wellund of the University of Cambridge. They published their research in the 5 April 2001issue of Sciencexpress. The research was funded by the European Union under the Information Society Technologies’ Future and Emerging Technologies program (IST FET).

Timeline: < 10 years

Funding: Government

TRN Categories: Nanotechnology & Materials Science and Engineering

Story Type: News

Related Elements: Technical paper, "Single Crystals of Single-Walled Carbon Nanotubes Formed by Self-Assembly" in Sciencexpress, April 5, 2001.

Advertisements:

May 30, 2001

Page One

VR tool aims high

Bulk nanotubes make clean crystals

Engine fires up electrical devices

Microscopic stamps make nanotech devices

How metallic are metal nanotubes?

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.