Hitting

the deck cools microdevices

By

Eric Smalley,

Technology Research NewsIt doesn't take a lot to overheat microscopic mechanical components like the tiny flakes of metal and semiconductor used in microelectromechanical systems.

And if these bits of material are moving parts mounted above the surface of the chip, the only way they can cool off is to wait for the excess heat to dissipate through the air, which is not a good thermal conductor.

Researchers at the University of Minnesota have developed a technique for cooling these components that is the equivalent of a blacksmith periodically plunging red hot iron into a bucket of water.

"If you have a microdevice, say a MEMS-type device... you can change its thermal conductivity by placing it in contact with its underlying substrate," said Joseph J. Talghader, an assistant professor of electrical and computer engineering at the University of Minnesota.

The method can be used to finely control the temperature of these devices. "Not only can you quench it, but you can actively control the thermal dissipation speed of [the device] by periodically placing it in and out of contact with the substrate," Talghader said.

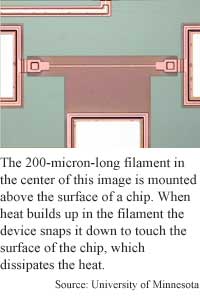

The researchers have built a series of microdevices made up of movable filaments of titanium-coated silicon mounted above a surface of the same material. The .75-micron-thick filaments range from 50 to 450 microns long and 6 to 20 microns wide. There are 1,000 microns in a millimeter.

When a filament heats up, its electrical resistance changes. Electrical resistance, or the ease with which electrons flow through a material, is easily measured. The researchers rigged their device to apply a pulse of electricity to the filament when it heated up enough to make its resistance cross a certain threshold. The pulse slapped the filament down to the surface, which rapidly drew heat from the filament.

The researchers were able to lower and raise the filaments much more rapidly than the bits of metal-coated silicon heated. This allowed them to precisely tune the filaments' thermal conductivity, or the rate at which the filament can transfer heat. In theory, the conductivity could be set to any level between the low conductivity in its raised position and the high conductivity in its lowered position, said Talghader.

The technique could be used to protect the sensitive MEMS components of thermal imagers, optical networking equipment and chemical labs-on-a-chip.

Thermal imagers use an array of metal elements to translate infrared radiation to electrical signals, which are then used to produce an image. Because they are very sensitive, they are prone to thermal overload, said Talghader. "These little MEMS elements that make up these [imagers] are designed to be extremely, extremely sensitive, and so if you are looking at something that is fairly dim and then all of the sudden something bright comes into your field of view you can often blow out the element," he said.

Telecommunications networks increasingly use arrays of tiny mirrors to direct the pulses of light carried over fiber-optic cables. "[The mirrors] are little plates of polysilicon with a sheet of metal on them. They're very thermally isolated and so they're very sensitive to the light that [hits] them," said Talghader.

And in the emerging field of microchemical systems, MEMS devices are used to mix tiny amounts of chemicals. Sometimes the resulting reactions produce sudden bursts of heat that can damage the devices, said Talghader.

"This is a new approach that has not been demonstrated before," said Yu-Chong Tai, a professor of electrical engineering at the California Institute of Technology. "The approach is sound and results are plausible."

"However, I... could not come up with some killer application for it," he said. "There are many interesting applications such as [infrared] imagers that will require the best thermal isolation one can get. Maybe what this approach can do is to provide tuning for each and every IR detector so the uniformity is better."

The method could be used in thermal imagers in three years, said Talghader. Practical applications for microchemical systems are probably 10 years away, he said.

Talghader's research colleague was Ryan N. Supino. They published the research in the March 19, 2001 issue of Applied Physics Letters. The research was funded by the Defense Advanced Research Projects Agency (DARPA).

Timeline: 3 years, 10 years

Funding: Government

TRN Categories: Microelectromechanical Systems (MEMS)

Story Type: News

Related Elements: Technical paper, "Electrostatic Control of Microstructure Thermal Conductivity," Applied Physics Letters, March 19, 2001

Advertisements:

March 28/April 4, 2001

Page One

Programming goes quantum

Diversity trumps fitness

Nanotubes paint clear picture

Hitting the deck cools microdevices

Magnetic fields move microbeads

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.