Disk-on-a-chip takes shape

By Eric Smalley, Technology Research NewsCheaper, faster mass data storage could arrive sooner rather than later thanks to an advance that bridges the gap between disk drive technology and microelectromechanical systems (MEMS).

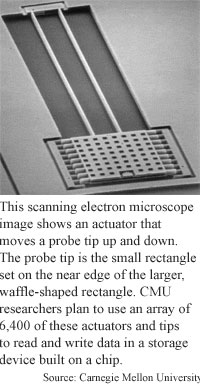

Researchers at Carnegie Mellon University have built a mechanism that controls read/write tips for a MEMS data storage device. MEMS are tiny mechanical devices made from silicon chips.

These storage devices can be made using largely the same materials and techniques as those used to produce computer memory and processor chips, making them potentially much cheaper than today's disk drives.

Storage MEMS also open the possibility of building an entire computer system on a single silicon chip, said L. Richard Carley, a professor of electrical and computer engineering at CMU. "In the long run you could build really low-cost embedded systems that are incredibly intelligent because they would have 5 [to] 10 gigabytes of mass storage coupled with a lot of processing power," he said.

The CMU device uses magnetic disk drive media fixed to the underside of an 8mm by 8mm silicon plate. The plate is attached to a larger piece of silicon by tiny actuators, or motors, that move the plate side to side and back and forth. The plate is placed on top of another that contains an array of 6,400 microscopic tips. Each tip will have its own actuator that moves it up and down.

The researchers have built and demonstrated a tip actuator and tip. Their next step is putting a magnetic read/write head on the tip, said Carley.

The tips will serve as the equivalent of a disk drive's read/write head, though instead of scanning the entire surface of a disk each tip will scan only a portion of the plate. Data will be written and read across all of the tips at once.

One of the biggest challenges to making a magnetic MEMS storage device was devising a means of controlling the distance between each tip and the surface of the storage media. The 8mm silicon plate is not perfectly flat at the nanometer scale, making the distance to the plate potentially different for each tip.

"We're actually building a little sensor that senses how far away the tip is, an actuator that pulls it up and a feedback loop that ... holds it at 30 nanometers spacing" said Carley. "So we have an active servo loop in every one of those 6,400 tips."

The large number of tips in the array makes the MEMS device potentially faster than disk drives. "The aggregate data rate can be really high even though the individual tip data rates are relatively low," said Carley. "Even at 100 kilobits per second, if I have 6,000 tips I'm running 600 megabits per second."

Individual disk drives have data rates up to about 20 Mbps, though arrays of disk drives can have much higher aggregate data rates.

Access time, or how long it takes to get any particular piece of data, is another important measure of data storage performance. "We can get very short access times because the [plate] only moves 100 microns. We can get [down] to the hundreds of microseconds instead of the multiple milliseconds that you get from a disk drive," said Carley.

The position of the plate can be controlled to within a few nanometers, making it possible to use bits that are as small as a few tens of nanometers square, said Carley. A nanometer is one millionth of a millimeter. Today, bits on the the most dense disk drives are about 50 nanometers long, though they will likely be a small as 25 nanometers within five years, he said.

Bits on disk drives are about 20 times wider than they are long because the tracks on the disks have to accommodate the microscopic flaws in their mechanical components that prevent the disks from achieving perfectly circular spins, said Carley. The bits on MEMS magnetic storage devices will be only as wide as they are long, so many more will fit on the same area, he said.

At 50 nanometers per bit, CMU's 8mm-square plate would have a capacity of 2 GB, Carley said. With 25 nanometer bits the capacity would be 8 GB, he said. These devices could also be an order of magnitude cheaper per bit than memory chips, Carley said.

There are several other MEMS data storage research projects underway, including efforts at Cornell University, Hewlett-Packard and IBM. Those efforts use media that is more akin to rewritable CDs.

"There are many imposing research challenges to making [MEMS data storage] happen. But if it works... you can envision non-volatile data storage ... at a fraction of the size, weight and power budget of existing disk drives, even the impressive 1-inch disk drive from IBM," said Albert P. Pisano, professor of mechanical engineering and electrical engineering and computer sciences at the University of California in Berkeley. Pisano is also a former DARPA program manager responsible for funding the CMU effort.

The CMU researchers should have prototypes of their data storage devices in two to three years, said Carley. The devices could be used for specialty applications within five years, and could be used in general commercial applications in 8 to 10 years, he said.

Carley's colleagues were James A. Bain, Gary K. Fetter, David W. Greve, David F. Guillou, Michael S. C. Lu, Tamal Mukherjee, Suresh Santhanam, Seungook Min, Greg Ganger and David Nagle of CMU, and Leon Abelmann of the University of Twente in the Netherlands.

They published their work in the May 1, 2000 issue of the Journal of Applied Physics. Another technical paper is scheduled to be published in an upcoming issue of the IEEE Transactions on Magnetics.

The CMU research was funded by DARPA. Ongoing research to develop systems based on the technology will be funded by NASA.

Timeline: <5 years, 8-10 years

Funding: Government

TRN Categories: Microelectromechanical Systems (MEMS); Data Storage Technology

Story Type: News

Related Elements: Photo, Technical papers "System Design Consideration for MEMS-Actuated Magnetic-Probe-Based Mass Storage" in an upcoming issue of IEEE Transactions on Magnetics, "Single-chip computers with microelectromechanical systems-based magnetic memory" Journal of Applied Physics, May 1, 2000

Advertisements:

October 25/November 1, 2000

Page One

Disk-on-a-chip takes shape

Shaky table top sorts parts

Forked nanotubes are tiny transistors

Society goes on data binge

Pulse harbors magnetic mystery

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.